Demonstration for Battery Rack, Temperature Management, and Fire Detec…

페이지 정보

본문

1. Company: aiWell

2. Objective

- To develop guidelines for temperature management inside ESS racks by measuring the temperature of battery modules during discharge while sailing and charging while generating power on the

M/V ULSAN TAEHWA.

- To measure the cooling performance of the ESS internal cooling system by measuring temperature changes caused by the operation of the internal air conditioner.

- To measure the heat generation range of Corvus batteries, derive an efficient cooling method for each part, and improve the capacity and control technique of the ESS container cooling system based on the results.

- To satisfy the fire spread prevention measures of the "Ship Battery System Guidelines (KR 2022)" proposed by the Korean Register of Shipping and the "Ministry of Oceans and Fisheries Notice - Electric Propulsion Ship Standards" proposed by the Ministry of Oceans and Fisheries.

3. Key Features:

- Installation of a battery management system for temperature monitoring.

- Measurement of temperature changes caused by the operation of the internal air conditioner.

- Measurement of the heat generation range of Corvus batteries.

- Derivation of an efficient cooling method for each part.

- Improvement of the capacity and control technique of the ESS container cooling system.

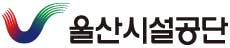

4. Equipment Installed: K-Type thermocouple temperature sensor and data logger

5. Results:

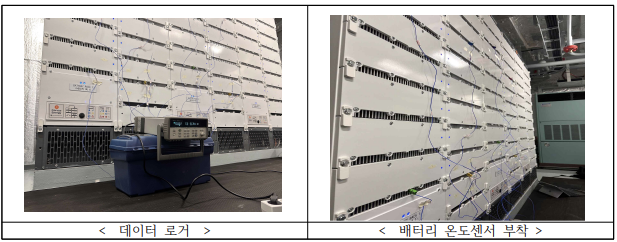

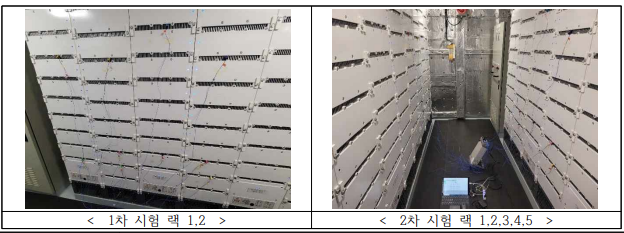

- 1st Test Summary:

Battery temperature was measured at 10-second intervals. Temperature data analysis showed that there was a temperature rise during battery discharge and charge. The temperature distribution was about 2℃ higher during charging than during discharge. The maximum temperature difference compared to the initial temperature was about 7 degrees (24℃/31℃).

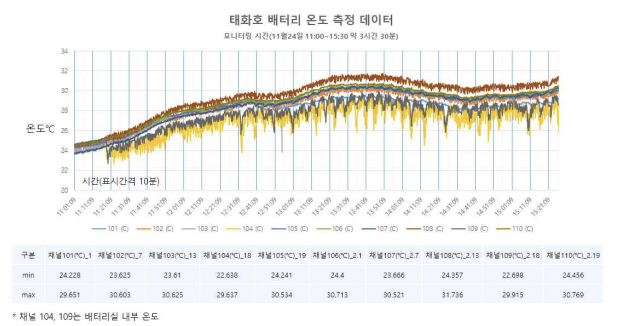

- 2nd Test Summary:

The initial starting temperature was 2~3℃ lower than the 1st test due to the influence of the external temperature. However, the battery heat generation pattern and the minimum/maximum temperature difference during operation showed similar results to the 1st test.

- Comparison of Actual Results with Planned Results:

The temperature change of the battery during operation was monitored using multiple temperature sensors. By identifying the temperature change pattern, basic data and test results faithful to the plan were obtained that can be used to establish criteria for stable battery temperature management during operation.

5-1 . Photos of the Test

- 이전글Demonstration for Wave Measurement Radar Shipboard. 24.02.27

- 다음글Demonstration for NQVM VRCS Equipment 24.02.27